Top 5 Challenges in IoT Implementation for Manufacturers and How to Overcome Them

The manufacturing sector is quickly recognizing the power of IoT (Internet of Things) to transform operations, streamline processes, and offer enhanced services to customers. From predictive maintenance to real-time monitoring and analytics, IoT opens new avenues for efficiency and growth. However, the path to implementing IoT solutions is fraught with challenges that can slow down progress or cause frustration for manufacturers.

In this post, we’ll explore the top five challenges manufacturers face when integrating IoT into their operations and how OpenRemote can help overcome them.

- Integration with Existing Systems

- Data Security and Privacy Concerns

- Lack of In-House Expertise

- Scalability Issues

- High Implementation Costs

1. Integration with Existing Systems

The Challenge:

Manufacturers often have established systems running core operations. Incorporating IoT data streams into these legacy systems can be complex. The challenge lies in ensuring seamless communication between the IoT infrastructure and pre-existing systems without causing disruptions to the business.

How to Overcome It:

OpenRemote’s open source IoT platform is built to handle flexible integrations, enabling manufacturers to bridge the gap between legacy systems and new IoT deployments. By supporting a variety of protocols, from industry-standard ones like MQTT to custom protocols, OpenRemote ensures that data from connected devices flows smoothly into existing operations.

With OpenRemote, you can achieve real-time insights, automated responses, and better decision-making while avoiding expensive system overhauls. The platform’s flexibility allows for tailored solutions to match your specific needs, ensuring smooth operation and business continuity.

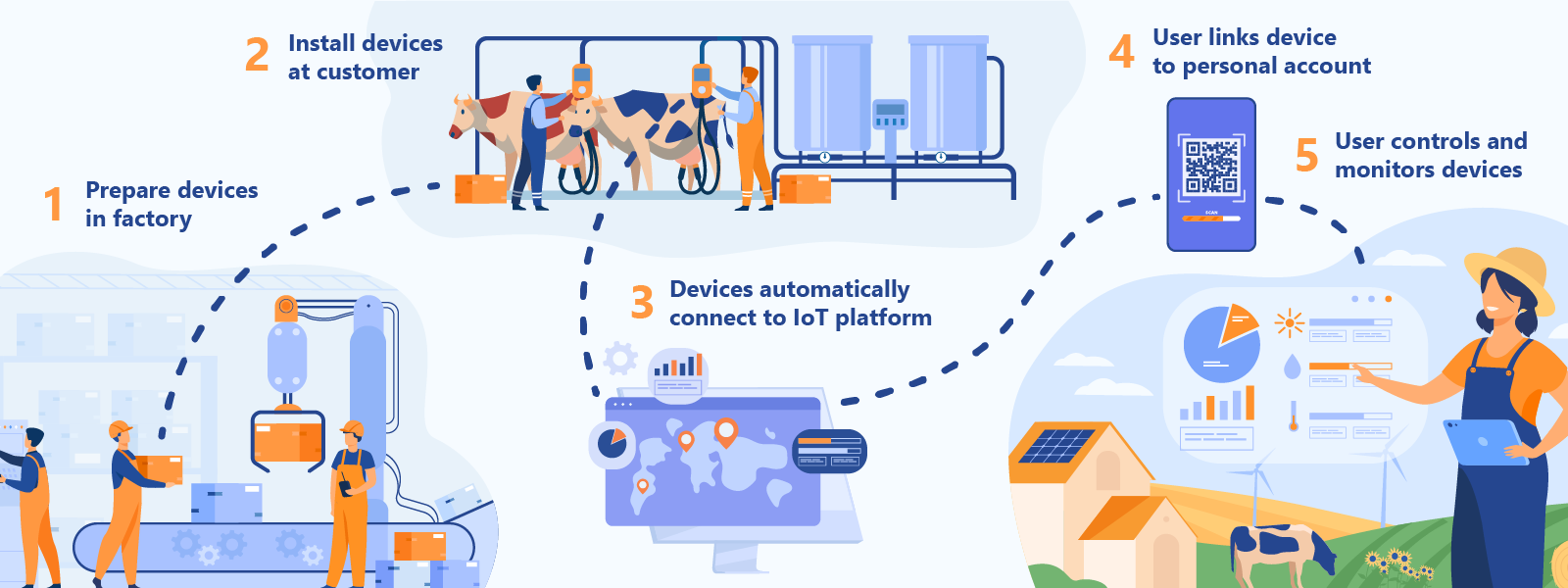

Out-of-the-box intuitive automation and data insights

2. Data Security and Privacy Concerns

The Challenge:

With IoT, manufacturers must gather and manage vast amounts of data. However, this also opens up vulnerabilities. Data security and privacy are significant concerns, especially in industries that handle sensitive operational or customer information. Manufacturers may fear that adding IoT devices increases their risk of cyberattacks or data breaches.

How to Overcome It:

OpenRemote ensures robust security with features like end-to-end encryption, role-based access control, and secure data transmission protocols. The platform also supports compliance with key industry regulations, such as GDPR, allowing manufacturers to implement IoT confidently while safeguarding sensitive data.

By leveraging OpenRemote’s secure IoT platform, manufacturers can rest assured that their operational data and customer information are protected while still taking advantage of IoT’s benefits.

3. Lack of In-House Expertise

The Challenge:

Many manufacturers don’t have the in-house expertise required to manage and maintain an IoT system. IoT projects demand a blend of skills, including hardware integration, software development, data analytics, and system maintenance. The learning curve can be steep, and finding or training talent in these areas is time-consuming and costly.

How to Overcome It:

OpenRemote was designed with ease of use in mind. Our platform offers an intuitive interface for managing IoT devices, configuring automation workflows, and visualizing data without the need for extensive programming knowledge. Additionally, our community-driven approach means that manufacturers can benefit from shared knowledge, tutorials, and support from other users and developers who are solving similar challenges.

For more complex needs, OpenRemote offers professional services to help you with the development, integration, and long-term maintenance of your IoT systems. With this support, even manufacturers with no in-house expertise can successfully deploy and manage IoT solutions.

4. Scalability Issues

The Challenge:

One of the main concerns for manufacturers is ensuring that their IoT solutions can scale as their operations grow. What starts as a pilot project often needs to be scaled across multiple production lines, factories, or even regions. Without careful planning, scaling can lead to performance bottlenecks and spiraling costs, especially if proprietary platforms impose heavy licensing fees for growth.

How to Overcome It:

OpenRemote’s open source nature provides the perfect foundation for scalable IoT deployments. Whether you’re adding a few devices or deploying thousands of sensors globally, the platform scales seamlessly to handle increased data traffic and device connections.

Additionally, OpenRemote’s architecture ensures that as your IoT network expands, the platform can handle increased device traffic and data streams without performance loss. With horizontal scalability, OpenRemote grows with your business, providing continuous support for your evolving needs.

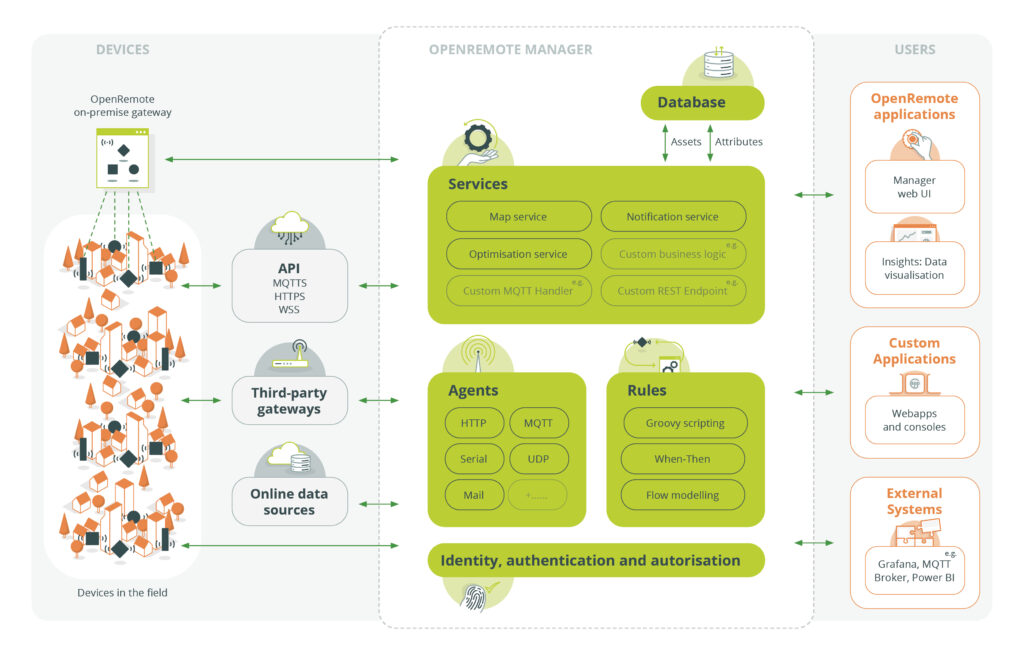

Platform architecture

5. High Implementation Costs

The Challenge:

The initial cost of implementing IoT can be prohibitive, especially for small or medium-sized manufacturers. IoT infrastructure requires an investment in hardware, software, integration, and maintenance. As a result, manufacturers may be hesitant to commit to IoT because of the uncertainty around ROI or fear that the costs could spiral out of control as the project scales.

How to Overcome It:

OpenRemote offers a cost-effective solution with its open source platform. This allows manufacturers to significantly reduce software costs, as there are no licensing fees for the core platform. You can start with a free and fully functional system, only incurring costs if you require customizations or premium support.

Moreover, OpenRemote’s ability to integrate with a wide variety of hardware devices and protocols enables manufacturers to reuse existing infrastructure instead of investing in entirely new systems. This further minimizes the upfront costs of IoT adoption, making it accessible to businesses of all sizes.

Conclusion

Implementing IoT in manufacturing can seem daunting, but it doesn’t have to be. By addressing the common challenges of integration, security, scalability, cost, and expertise, manufacturers can unlock the full potential of IoT to improve operations, reduce costs, and deliver value-added services to their customers.

OpenRemote’s open source platform offers the tools and flexibility needed to overcome these challenges, allowing manufacturers to seamlessly integrate IoT into their existing processes and scale for future growth. Ready to explore how OpenRemote can help you overcome your IoT challenges? Check out the demo, our code, or contact us!